|

Sludge Dewatering

Price 15000 INR/ Kilograms

Sludge Dewatering Specification

- Storage

- Cool and Dry Place

- Shelf Life

- 2 Years

- Solubility

- Soluble in Water

- Packaging Type

- HDPE Bag, Drum

- Chemical Name

- Sludge Dewatering Polymer

- Physical Form

- Powder

- Grade

- Industrial Grade

- Purity(%)

- 99%

- Type

- Sludge Dewatering Chemical

- Application

- Industrial Sludge Treatment, Wastewater Purification, Municipal Sewage Plants

Sludge Dewatering Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Supply Ability

- 200 Kilograms Per Day

- Delivery Time

- 1 Week

About Sludge Dewatering

Sludge Dewatering FlocculantWhy flocculants are used in dewatering application?

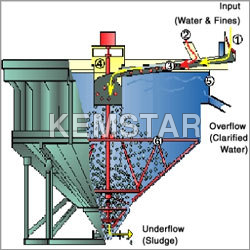

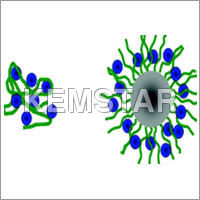

- Flocculants are used in solid liquid separation to increase the efficiency of the unit operation equipment by increasing the density difference between solid and liquid phases.

- Stronger and bigger sized flocs are always suitable for the decanter as it provides the required density difference to get maximum solid recovery in the wet cake, leaving behind clear centrate.

- IN belt press, the selected flocculant should be able to make flocs as well as increase the drainage of the water separated thru belt in limited time.

- In dewatering application, the dose levels are always mentioned in "Kg/T of dry solids" as it takes care of fluctuation in the % solid in the feed and it gives better idea about the usage of flocculant per ton of dry solid processed/dewatered.

| Kg/T of dry solids = | Flocculant dose in ppm Solid in slurry in gm/ltr |

Equipments used for Dewatering in Industries.

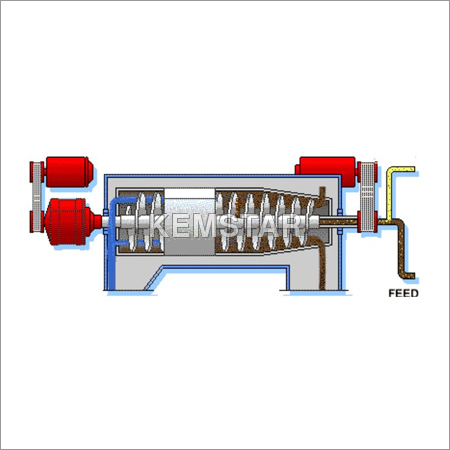

- Horizontal continuous Decanters

- Vertical bowl batch type centrifuges

- Multiple Belt Filter Press

- Single belt Filter press

- Bag filters

- Plate & frame Filters

- Extensive range of flocculants for every substrate

- Available in High to ultra Molecular weight with anionic, cationic & non ionic charges.

We provide services for the extensive field trials for the selection of best flocculants and plant trails to stabilize the application.

Please contact Kemstar with the details of the application & process parameters to enable us to suggest suitable product to you. If needed our field person will make visit to conduct lab dewatering testing at site to select the best performing flocculant

Why Choose Our Sludge Dewatering Polymer?

Our chemical formula guarantees effective sludge dewatering, reducing disposal costs and enhancing the efficiency of wastewater purification. Its 99% purity ensures maximum activity, while its powder form dissolves swiftly in water, making it consistent and easy to dose during processing.

Reliable Packaging and Storage

Packaged in robust HDPE bags or drums, our sludge dewatering chemical is safeguarded against moisture and contamination. For best results and prolonged shelf life, store in a cool, dry place. This ensures the polymer remains effective up to 2 years after production.

FAQs of Sludge Dewatering:

Q: How is the sludge dewatering polymer applied in industrial or municipal settings?

A: The polymer is added directly to the sludge or wastewater stream, where it dissolves rapidly in water, promoting flocculation and separation of solids from liquids. Precise dosing ensures optimal dewatering results, reducing the volume and weight of the final sludge.Q: What are the main benefits of using this sludge dewatering chemical?

A: The chemical significantly improves the efficiency of sludge treatment by accelerating solid-liquid separation, lowering disposal expenses, and minimizing environmental impact. Its high purity ensures consistent results across multiple industrial and municipal applications.Q: When should the sludge dewatering polymer be used in the treatment process?

A: It should be added during the sludge conditioning phase, before mechanical dewatering equipment is engaged. This timing allows the polymer to bind fine particles and enhance water removal during centrifugation, filtration, or belt pressing.Q: Where can this product be sourced in India?

A: As a dedicated distributor, supplier, and trader, we deliver our sludge dewatering polymer to clients throughout India, supporting industrial facilities and municipal plants with reliable supply and technical guidance.Q: What is the recommended method for storing the sludge dewatering polymer?

A: Store the powder in its original HDPE bag or drum, placed in a cool, dry location away from direct sunlight or moisture. Proper storage maintains its efficacy for the full 2-year shelf life.Q: Can the sludge dewatering polymer be used with all types of mechanical dewatering equipment?

A: Yes, the polymer is compatible with most standard dewatering machinery, including centrifuges, belt presses, and filter presses, ensuring adaptability to various plant operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wastewater Treatment Category

Poly Aluminium Chloride

Minimum Order Quantity : 100 Kilograms

Application : Swimming Pool Water Treatment

Type : Other, Poly Aluminium Chloride

Chemical Name : Other, Poly Aluminium Chloride

Grade : Industrial Grade

Purity(%) : 99%

Anionic Flocculants

Minimum Order Quantity : 100 Kilograms

Application : Swimming Pool Water Treatment

Type : Other, Anionic Flocculants

Chemical Name : Other, Anionic Flocculants

Grade : Industrial Grade

Purity(%) : 99%

Ro- Antiscalant

Minimum Order Quantity : 100 Kilograms

Application : Swimming Pool Water Treatment

Type : Other, RoAntiscalant

Chemical Name : Other, RoAntiscalant

Grade : Industrial Grade

Purity(%) : 99%

Branch Address

Kemstar Process Solutions,

190/2, Toran Apartments,

Anandvatika Society,

Sector 22, Gandhi Nagar 392022

Phone: 022 25004810

Contact person: Mr. Abhay Doshi

|

KEMSTAR PROCESS SOLUTIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry