|

Silicone Defoamer

Silicone Defoamer Specification

- Product Name

- Silicone Defoamer

- Product Type

- Silicone Defoamer

- Material

- Silicone

- Color

- Transparent

- Application

- Industrial

- Shape

- Different Shape

- Hardness

- Rigid

Silicone Defoamer Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 7 Days

About Silicone Defoamer

Following the philosophy of bringing best quality solutions to the customers, we are engaged in supplying a quality range of Silicone Defoamer. These defoamers are sourced from the most reliable and trusted vendors of the market with the help of our expert procuring agents. In various industries like water treatment, oil & gas, cement and food processing, these defoamers are widely used. We offer our Silicone Defoamer at cost effective prices to the clients.

Features:

-

Precise formulation

-

Highly effective

-

Prevents the formation of foam

Silicone Defoamer Antifoam

What is foam?

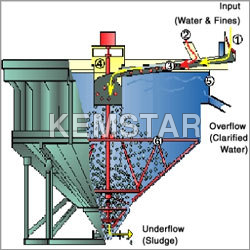

Foam is a dispersion of air or other gases in a liquid or solid.

Industrial processing foams cause problems:

- Overflow vessels, low productivity

- Increase housekeeping costs

- Interfere with processing

- Damage materials

- Slow drainage during drying

- Interfere with packaging

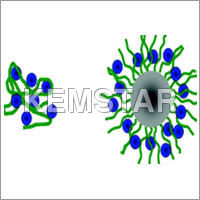

Why and how is foam controlled?

There are two ways to control problem foam:

- Defoamers: Destroying with Defoamer. Chemicals or formulated products that destroy, or knock down, foam that has already formed.

- Antifoams : Chemicals or formulated products that prevent the Formation of foam.

- Water & Wastewater Treatment at ETP, STP

- Lubricant Formulations

- Agro formulations

- Water based formulations

- Cement concrete manufacturing

- Oil & Gas segment

- Food processing

- Industrial Fermentation application

- Chemical processing

Please contact Kemstar with the details of process parameters & application to enable us to suggest suitable product to you.

Efficient Foam Control for Industrial Needs

Silicone Defoamer offers superior foam suppression in a wide range of industrial processes. Manufactured using rigid, transparent silicone, it ensures compatibility with diverse formulations and operational conditions. Its versatility in shape and ease of application helps industries curb production issues caused by unwanted foam, enabling smoother operations and improved process control.

Distributed Nationwide in India

As a trusted distributor, supplier, and trader, we provide Silicone Defoamer all over India. Our extensive supply network ensures timely delivery and local availability, supporting industries in maintaining uninterrupted production. Customized forms and volumes let businesses select the best fit for their specific requirements.

FAQs of Silicone Defoamer:

Q: How is Silicone Defoamer used in industrial processes?

A: Silicone Defoamer is typically added directly to foaming systems at specific stages, depending on the process requirements. It disperses quickly in water- or solvent-based formulations, effectively controlling foam build-up during mixing, processing, or transfer operations.Q: What industries benefit most from using Silicone Defoamer?

A: Industries such as textiles, chemicals, food processing, paper manufacturing, and wastewater treatment frequently utilize Silicone Defoamer to manage and eliminate foam, ensuring smooth and efficient operations.Q: When should Silicone Defoamer be introduced during production?

A: The defoamer can be added at the beginning of a process to prevent foam formation or during production when foam is detected. The precise timing depends on the nature of the process and level of foam anticipated.Q: Where can I source Silicone Defoamer in India?

A: Silicone Defoamer is available through leading distributors, suppliers, and traders across India, facilitating local and nationwide supply for industrial clients.Q: What is the process for applying Silicone Defoamer?

A: Application involves adding the specified amount of defoamer directly to the foaming zone or mixture, ensuring thorough dispersion. It is suitable for both continuous and batch processing environments.Q: What are the advantages of using a transparent, rigid Silicone Defoamer?

A: Its transparency ensures it does not alter the appearance of products, while its rigid form allows for stable performance under various temperature and chemical conditions, making it ideal for demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Silicone products Category

Silicone Fluid

Minimum Order Quantity : 100 Liters

Product Type : Silicone Fluid

Hardness : Soft

Application : Industrial

Shape : Fluid

Color : Transparent

Silicone Release Agent

Minimum Order Quantity : 100 Kilograms

Product Type : Silicone Release Agent

Hardness : Rigid

Application : Industrial

Shape : Different Shape

Color : Multicolor

Super Wetting Adjuvant

Minimum Order Quantity : 100 Kilograms

Product Type : Super Wetting Adjuvant

Hardness : Rigid

Application : Industrial

Shape : Different Shape

Color : Transp

Branch Address

Kemstar Process Solutions,

190/2, Toran Apartments,

Anandvatika Society,

Sector 22, Gandhi Nagar 392022

Phone: 022 25004810

Contact person: Mr. Abhay Doshi

|

KEMSTAR PROCESS SOLUTIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry